The larger part of Africa’s population do not have access to “processed” fuels like natural gas or modern cooking equipment. This means they are primarily dependent on open wood fires, a method of cooking that it extremely inefficient and harzardous to the environment.

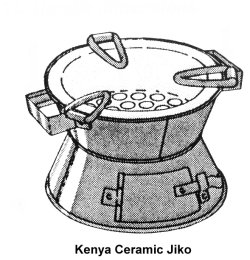

The Kenya Ceramic Jiko (“jiko” is the Swahili word for cooker) solves two problems simulataneouly by addressing the issue of high cost of raw material for making the cooking equipment as well as reducing the amount of biomass required to cook by using available energy more efficiently.

This ingenious application of appropriate technology is composed of a fired ceramic heat containing liner fitted inside a metal housing. This housing is typically made from metal sheeting from discarded packaging – such as the ubiquitous 55 gallon steel drum – that would otherwise have ended up as hazardous waste in the environment. The liner essentially acts as an insulator when burning wood or charcoal containing the heat generated to ensure that it goes to cooking rather than escaping into the environment. This means that the ceramic cooker typically uses between 25 to 40% less fuel than a regular jiko.

You can find more information about this ingenious invention at the following links:

– Daniel Kammen’s Cook stoves for the developing world.

– Equator Initiative’s A burning concern.

Hugh Allen has also published a handbook of making Kenya Ceramic Jikos through the Stylus publishing house.