Piki piki means motorbike in Kiswahili

This gadget was created to solve a real problem with biogas – getting the dung to the system quickly and efficiently. Motorbikes are the taxi’s of Africa so why not? Before I tell you about the above gadget I just want to remind you about the problems we have been having to solve to get the biogas to work at home.

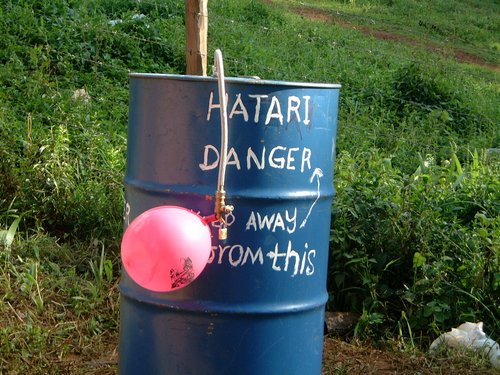

Installing biogas at home has a real experience in afrigadget – we have figured out by trial and error how to get the gas under pressure –

At first we tried using water pressure, but when we stepped back and looked at it we realized that it really wasn’t simple or appropriate for bush applications ..

In fact, all we needed to do was to put pressure on the bags.

The pressure wasn’t enough to run the stove until we modified the stove jets by enlarging them slightly.

Next we had to figure out how to get the dung to my digester – you see I don’t own cows but my neighbors who live a few kilometers away do and are selling it at a very nice rate of Ksh 50 (70 US cents) for two large buckets . The owners are happy to see the dung as it accumulates in the nighttime stockades and attracts annoying flies that carry diseases if left on the land.

The problem I face is common to many folks around here, we rent houses but we don’t have livestock. But there are huge cattle farms around us. So Dominic came up with a solution that creates jobs and moves poop quickly and efficiently.

So we went to the local juakali welder on the roadside to create a dungmobile ..a trailer designed specially for cow dung!

We tested it with a human load to ensure it is balanced … each bucket weighs about 50 kg.

And the first delivery arrived without a problem! 🙂 Big Thanks to Dominic Wanjihia who seems to always have a simple solution to any problem.

I know you are wondering, if it’s that easy, then why doesn’t everyone use biogas?

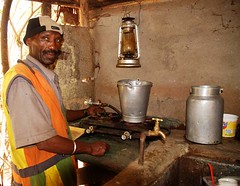

Now that I’ve got biogas running my kitchen I wonder why so few people have done so in Kenya. There are countless articles, publications, websites and people who will tell you that biogas is the most economical and environmentally sustainable way to produce energy. In fact, the benefits of Biogas have been known for tens of years, and hundreds of systems have been built in Kenya. But it hasn’t really taken off – few of the installed systems are actually working and the uptake of biogas systems at a domestic level has been slower than slow – it’s virtually non-existent. A review of biogas in Kenya reports that technical breakdowns has discouraged uptake but the main limiting factor is cost.

Here’s a simple comparison of costs – from continuing using charcoal/fuelwood or Kerosene and LPG to using various biogas options.

| Options | Cost (US$ ) | Time to install (days) | Labour | Maintenance | Durability |

| Fixed dome | 1,500 – 2000 | 21 | 5 people | Low | Decades |

| Floating top | 2,000 – 3,500 | 21 | 5 people | Low | Decades |

| Flexi bag envelope | 400 | 1 | 1 person | Low | 10 – 15 years |

| Fuelwood or LPG cylinders | 200 (per year) | 0 | 0 | low | Decades |

For a simpleton like me these figures are immediately revealing – it takes 2 years to pay off a flexibag digester after which domestic fuel is free for at least the next 10 – 13 years. For the underground systems you have got to be hugely rich, or suffering from environmental guilt to make the decision to switch to biogas – from an economic perspective it will take 10 to 20 years to pay back. You could grow your own trees and make your own charcoal in that time frame….

Why is it so expensive for the constructed biogas systems? Because most of the biogas systems in use are constructed systems requiring engineering and masonry, they are very expensive, take weeks to install, require experts, and intensive follow up. If they go wrong it’s a major engineering task to fix it. This is why we are promoting the flexible bag option for domestic and small industry use.

Congratulations to Skylink Award winning Kenyan biogas innovators

We would ;like to congratulate Skylink Innovations who have just won a the Ashden 2010 Award for their biogas installations in Kenya.

I thought skylink was an airline… Biogas operated planes???

Their industrial scale system costs Ksh 1.6 million (US$ 19,753). Such installations may need to be financed by the Government institutions where they clearly make enormous economic and environmental sense for schools, prisons and other large institutions.

For small scale house hold units, we need solutions that will compete against the cost of installing LPG or using charcoal, firewood or kerosene stoves. When we talked to local Maasai near Nairobi they found the flexi bag systems appealing because they could be purchased with the sale of just 2 or 3 cows, can be rolled up and moved when they migrate, and it saves the women the work of searching for firewood, it’s hygenic because water can be heated for bathing children, while it also removes dangerous piles of rotting cow dung near the homesteads which are breeding sites for biting and disease carrying flies which affect livestock and people.