Or How to get your camel milk to market in 40 degree C climate.

My brother Dominic Wanjihia invented this gadget which he calls Fine Lined Evaporative Cooler, for rural application in Somalia – the cooling of camels milk for transportation . He was working on a project for VETAID, Somali Pastoral Dairy Development Program – SPDDP,in Burao, Somalia June 2008. All this content belongs to Dominic who has allowed me to post it here- please seek his permission to use this content elsewhere dwanjihia@yahoo.com

Evaporative cooling technology

The evaporative cooling concept has been used for centuries in countless applications. Cooling occurs when a fluid changes state from liquid to vapor. Put simply, evaporation. In order to evaporate, the liquid requires energy or heat. It acquires this heat energy from its immediate surrounding. As the surrounding gives up this heat, it lowers in temperature or cools.

The rate at which evaporation occurs depends largely on two main factors, the amount of heat available and the humidity in the air.

The cooler must also be shaded from direct sunlight otherwise the surfaces absorb UV heat and warms up, becoming ineffective as a cooler.

In short

Evaporative cooling devices work most efficiently in windy, dry and shaded conditions

Charcoal cooler

Everyone knows how to make charcoal fridges. After carrying out extensive tests on evaporative coolers in hot arid Burao, Somaliland, with day temperatures as high as 36OC in the shade, the charcoal would absorb ambient heat from the air and as opposed to cooling, would warm up the interior compartment.

Imagine wearing a wet thick winter jacket under the palms at a breezy beach. The jacket acts as a wetsuit and will insulate your body preventing heat from escaping.

Fine lined cooler

However, imagine wearing a wet skintight t-shirt in similar conditions. The water evaporates quite rapidly and cools your body.

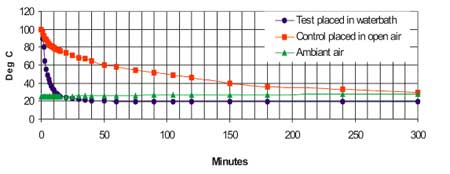

I applied this concept to the cooler prototype pictured and achieved startling results. The cooler would drop as low as 15.5OC at night when temperatures averaged 25OC and maintain under 17OC during the day at average temps of + 32OC.

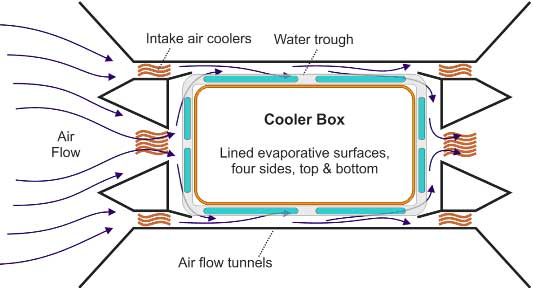

Construction

An elevated metal box is lined interior and exterior with a fabric. In this case I used locally available corrugated galvanized iron sheets for the container and sisal sacking fabric for lining. The upper ends of the fabric overhang in a water trough that rings the top of the cooler. Capillary action causes the water to slowly trickle over the inner and outer surfaces. A small vent keeps the interior air circulating and wind guides or tunnels direct air flow over the exterior surfaces. A low speed small solar powered fan can be incorporated in areas where there is not a constant breeze.

How it works

The circulating air in the interior causes evaporation on the wet surfaces. The necessary energy is acquired from the contents hence cooling them and is transfers to the iron sides.

Wind guides or tunnels direct an airflow over the external sides. The evaporation that occurs acquires energy from the sides causing further cooling of the interior.

Construction design

Cool-box with water-bath interior for rapid milk cooling application– Collection Point Cooler

Walk-in cold-room for vegetable storage

Vehicle mounted for long distance transporters

Features (Comparison to conventional charcoal coolers)

Very simple construction

Corrugated galvanized iron or GI sheets increase the surface area

Wind tunnels guide air flow efficiently over evaporation surfaces

Air flow coolers at tunnel entrances

Being galvanized, the sheets are long lasting

GI sheets are affordable and available in most rural areas

Secondhand sacking fabric is available in virtually every vegetable market

The simple capillary action dripping system replaces more complicated dripping apparatus

Convection current system to increase water-bath cooling efficiency

In hot arid regions, cooling the warm ambient air before it reaches the wet evaporation surfaces increase efficiency. Note. Setup for airflow from either direction

For further information and other rural development concepts and innovative designs, Dom can be reached on

mobile tel +254 722 700 530 dwanjihia@yahoo.com

I have used this method to cool food boxes while traveling on bicycle (in much cooler temperatures than yours), but I had to abandon it after a week or so. I had no way to wash the cloth that I had around the boxes often enough, and effectively enough, so the cloth soon started to smell so bad I decided I don’t want to risk food poisoning. The bacteria that the cloth sustained would soon have been in my food. I imagine camel milk goes bad as easily as cow milk, so in your temperatures, how often do you have to throw away the sacking fabric and replace it with new to ensure food safety?

Thanks Tom, good question! I’m going to ask him to respond directly. Paula

We used to wrap a wet bandana around our water bottles when camping in the desert – it always amazed me how well it worked.

Hi again Tom, Dom is out of town but on phone he told me that he’s using chlorine but his grand plan in the long term is to grow moss to replace the hessian sacking …..he’s convinced it’ll work because moss can dry out and refresh very quickly though I suspect it would not solve the hygiene problem.

Moss sounds very good to me, actually. Also, I think the charcoal fridge is much more hygienic than fabric. Meanwhile, I have been pondering if frequently changing the fabric can worsen the problem, especially if it isn’t easy to wash one’s hands after handling the fabric. That was my problem when I stopped by the roadside for lunch while cycling. Of course, when I had wrapped my food boxes in cloth, I had to touch the cloth every time I stopped to eat, whereas with evapocooler you don’t need to touch the fabric every time.

Anyway, I’ve see a video somewhere about a method to sterilize drinking water just by leaving it in a clear bottle in sunshine. In many parts of Africa, sunshine is strong enough for sterilization. Where I live, there’s no chance. Sack fabric of course is not quite the same as a clear bottle, but there could be a chance that the fabric too can be sterilized by keeping it in sunlight all day. But then, again, how often do yo want to touch the damp fabric…

Hi Paula, and hi Tom

Evap cooler

This design is specific for large scale and porervty eradication in remote rural areas. Tom, as a cycle user, you are probably adopting the same fine line technology but on a micro level – hence bacteria proliforation. If there is a need on a commercial scale, i’m more than confident i can come up with a solution.

On the otherhand –

The moss concept increases the evaporation surface area – hence increases cooling.

Moss is organic is clean, can begotten anywhere and it works.

Note also, low concentration chlorine will not destroy Moss.

UV

Yes, UV desroys most harmful bacteria in “clear mater”. UV cannot penetrate brown river water. It is applicable in settled waters – dams, lakes ect.

Be good, dom

This design could most likely be optimized, so that it could cool down the

milk or whatever even further. It would probably be a good idea to

involve some engineers that specialize in cooling technology in further developement or at least ask them for some advice.

Another amazing fact – according to the Dairy Farmer http://www.havemilk.com/article.asp?id=1485 In the hot desert, camel milk lasts longer than other types of milk. It can last for seven days at 86 degrees Fahrenheit (30 degrees Celsius), and will last for three months when properly refrigerated.

Interesting fact, but hardly amazing, since camels live in the desert, they have probably adapted so their milk glands produce more temperature stable milk.

Anyway, some guys at Stanford are also developing a low-cost refrigeration system, but on a completely different basis. Se the TED talk:

http://www.ted.com/index.php/speakers/adam_grosser.html

The thing about technologies presented on this blog, there all great and

all, but there’s lots of room for improving them in terms of efficiency,

cost, ease of use, etc. These inovative people should work more closely

with local universities.

While it is cool it aint exactly new and innovative like the article is proclaiming,indeed Dominic Wanjihia would even have a hard time laying claim to this as an invention as this kind of thing has been around for a very long time and is nothing more than a slight variation of `The Coolgardie Safe´ invented by Arthur Patrick McCormick in australia way back in the 1800’s

http://en.wikipedia.org/wiki/Coolgardie_safe

still quite a thing nonetheless

I am not sure why there needs to be any buzz around this type of cooler. In India, we have used the same concept for thousands of years. It is really cheap and works effectively. It is called a ‘Matka’. Almost any Indian will tell you that it works more effectively than the device you described and it costs about a dollar or less. The size of ‘Matka’ for that price (<$1) holds more than a gallon of liquid.

And by the way, it is also called an earthen pot.

The African sand pot would seam to be a better idea, the materials can be localy produced and and are cheaper.

http://techafric.blogspot.com/2008/04/rural-cooling-system.html

Back 10 years ago during the Scouts’ camps and Jamborees, we used the same concept to cool our food. Our concept was with papier mache instead of fabric or charcoal. It was very effective, as well as a way of recycling pieces of paper