This is a proposed way to maximize the usage and efficiency of the KVA Flexible Solar Portable Kit by Dominic Wanjihia. Dominic was awarded one of the Flex Kits at the recent Maker Africa Faire in Accra after showing off some amazing new ideas.

One of the cheapest form of transport in Kenya is the “Boda Boda” literally meaning “Border-to-border”, a bicycle ride from one countries boarder immigration offices through no-mans land to the immigration offices of the bordering country customs office.

This mode of transport is non discriminatory and is used by people of all walks of life. from school children, market goers, workers, business persons, etc. The popularity is partially due to the speed and convenience as one does not get stuck in traffic. In the Lake basin town of Kisumu there are estimated to be over 500,000 BodaBoda’s. In the whole county, in excess of 1,500,000

The BodaBoda rider normally works from as early as 4.30a.m. to as late as 10.00p.m. depending on security in the area. He relies greatly on his mobile phone for clients to call for his services. His peak cycling times are early morning, lunch hour and dusk as persons head home from school and work. Translates to 4 – 5 hours in total daily riding time.

Due to the lack of know how and the complexity of electronics, the lack of power storage (i.e. a battery, and the cost) the Cycle dynamo is only effective for charging items and lighting while he is riding. Also, due to space or lack of, cost, insecurity and theft, attaching “Hard” Solar panels to the bikes has never been a viable sustainable option.

However, with the introduction of the Flexible Panels I believe wearing the panels on his back eliminates all these constraints. It also means he is generating power from sun-up to sun-down, an average of 12 hours a day.

Attaching the flexible panels on his back ensures:

- His phone is always charged guaranteeing customer accessibility

- He has light at home from the LED’s so saves on heavy power bills

- He always has an emergency light with his – LED

- The panels will not get stolen

- One can also offer charging facilities to client being carried

Other users

The BodaBoda is not the only potential user of the Flexible Panel by wearing it. Anyone spending long hour’s outdoors is a candidate. The farmer, fisherman, hawker’s and peddlers, city council outdoor workers, tourists, campers and hikers – just to mention a few.

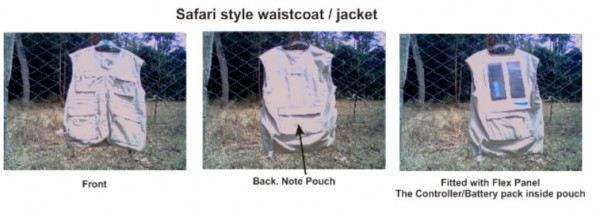

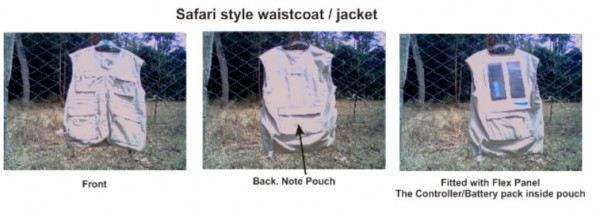

Attaching the Panel

It can be attached in a variety of ways. Velcro, Pop Buttons or simply attach Rucksack like straps so it can be worn with any garment. In the latter case the small pouch containing the controller and battery is attached to the back of the panels with Velcro.

If you would like to get in touch with Dominic, you can reach him at dwanjihia@yahoo.com or by phone at +254722700530