I’ve been having a great time in Accra, but not nearly enough time to spend on the details of every cool product or invention that I see. In the meantime, here are a couple pictures from around Ghana that will whet your appetite for what is coming up in the next week:

Author: Erik Hersman

Mechanics and Tailors

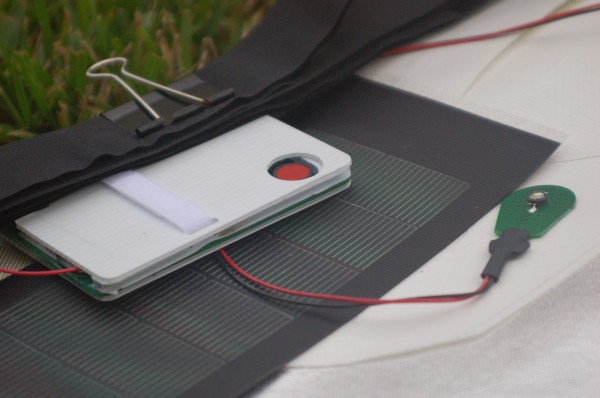

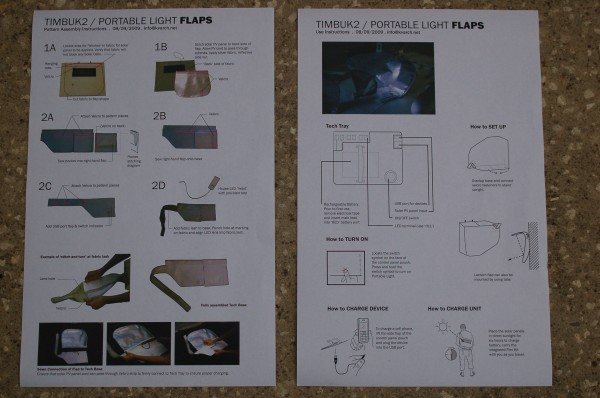

This is part of an ongoing series of posts on the FLAP bag project, a collaborative effort by Timbuk2, Portable Light and Pop!Tech. We at AfriGadget are helping to field-test these bags that have solar power and lighting on them, and get interviews of the individuals using them.

I’d like to upload some of the video from today’s first big day in Ghana, but bandwidth considerations make that a little difficult right now. Instead, I’ll give an overview and show some pictures.

Mechanics

Henry Addo is a colleague of mine at Ushahidi, and he’s also the Ghanaian representative who is helping me hand out the bags, do interviews and have fun… He’s also a motorcycle rider, so I made sure to pack my helmet before leaving. We set off in search of likely prospects for both the FLAP bag project and Maker Faire Africa.

I started out on a 250cc Honda streetbike that made me feel a little like Bowzer in Mario Kart. Fortunately, our first stop of the day was at Henry’s local motorcycle street mechanic at which I saw a beautiful 600cc Yamaha Terere being fixed up. The owner happened to be there, and he was game for a 2-day swap (with about $10/day thrown in for good measure…)!

This was also the first place that we started showing off one of the assembled bags to gauge the kind of reaction that we would receive from people. We didn’t do any formal interviews here, but had a good time of questions and people came up with some interesting thoughts on the use of the bag.

The head mechanic absolutely loved it, recounting the many times he was traveling around Ghana and needed light at night to fix his motorcycles.

The real estate businessman wanted to know the cost, thinking he would buy one right now for $100 from us (for bragging rights). Though he thought there was a market for them in Accra, that the real buyers would be found in rural villages.

The used-goods businessman wondered what would happen to the solar system if you tried to wash it to clean the bag. I didn’t have an answer, but I said that I thought it would be durable.

Tailors

We ran all over town trying to find tailors of adequate skill to assemble the bags that had come in pieces. It turned out being a little bit of a challenge, but things took a great turn for the better and we found 2-for-1 going on in a market. Elijah and Mohammed both traditionally use West African cloth to make both jackets and bags, however, they were game for this challenge (especially as it scored them a free bag).

Both tailors spent a great deal of time examining the textiles used and they made comments about the quality level of the bag. Interestingly, they didn’t think they would use the bags that much themselves, but they did think that their wives would find them useful.

I did full interviews with both of them, and will upload those in the near future. Henry will be going back to them in 2-3 weeks to see what has happened with the bags and how they are being used.

Knowing that we wouldn’t find too many others that could make the bags from the pieces we had, we also wanted to challenge them to something even more interesting. We asked what they would do if we gave them a basic portable light kit (2 solar panels instead of 1) and tried to make a bag with it, using traditional cloth elements and no set design pattern. Both decided to give that a try as well, with the caveat that some material would be hard to find, and we’ll report back on the outcome.

Final Presentations at IDDS Ghana

The International Development Design Summit is put on by Amy Smith and her students at MIT. This year it took place in Kumasi, Ghana – which will be followed by Maker Faire Africa this weekend in Accra, where some of their work will be shown.

Here’s a quick list of the projects they have been working on over the last five weeks:

– A press that speeds up the process of extracting oil from shea nuts

– A device for generating electricity from a playground carousel

– A machine for making recycled plastic products from used water sachets

– A set of tools for threshing groundnuts

– A mechanism for producing chlorine from salt water using readily available materials

– A simple, low cost battery made from local materials, for household lighting and other uses

– A human powered grating machine for speeding up cassava processing

– A thresher to improve the quality of rice by preventing stones from mixing with the grains

– A chlorine dispenser for disinfecting drinking water

– A family friendly latrine designed to promote use and hygiene among young children

– A device for monitoring the growth of children under five through cell phone technology

– A container that extends the shelf life of tomatoes during transport and storage

The importance of being in Ghana

Niall Walsh has written this information about how the importance of the move to Ghana for this year’s IDDS was to both MIT and the participants:

The main difference between IDDS Ghana and IDDS in MIT is the proximity to community partners and potential end users of the projects. IDDS prides itself on the spirit of co-creation and this movement from the States to Africa is a crucial one in line with this vision. The difference between participants sitting in lecture halls in MIT, learning about international development and the importance of speaking to at least fifty villagers before designing a technology, and actually living with and talking to hundreds of villagers all over the country, is immeasurable. In total IDDS this year worked with ten villages throughout the Bromg – Ahafo and Ashanti regions and teams had the chance to make three separate two night visits (spread throughout the design process to make sure they had input into every stage) to these villages. Among a huge number of other factors, the simple experience of having end users actually become extremely excited about your prototype, and seeing them test it out, is an incentive for teams to continue their project after IDDS.

Another way in which IDDS interacted with the local community, rather than simply for it, was through it’s interactions with Suame Magazine. This is an engineering cluster located in the centre of Kumasi, spanning twenty miles and with a working population of over 200,000 people. There are approximately 12,000 independent micro, small and medium enterprises located in the area and their main activities of vehicle repair and metal fabrication (welding and casting) are renowned for their ingenuity all across West Africa. During the summit, participants worked extensively with these engineers and mechanics in the ‘Magazine’ and had the chance to share ideas, techniques, and technologies with each other

The point has been stressed home at this year’s IDDS that these villagers involved in the process, as well as the workshop guys in Suame, are partners in the design process, rather than simply people we should talk to along the way. Without these partners, the technologies presented tomorrow at the Great Hall would quite simply not be possible, and I think that knowledge, in and of itself, will prove invaluable to our participants as they continue to work in international development after the conference. In light of this, five villagers from each village, as well as workshop managers from Suame, will be provided transport, accommodation and food to come to the final presentations to see all the different prototypes.

Systems have also been put in place to ensure that the projects worked on at this year’s IDDS will continue to be worked on after IDDS. There are project grants and partnership grants available for the teams and there will also be a full time country liaison for Ghana, responsible for integrating the technologies into all of our partner villages, as well as sourcing new villagers and markets to help disseminate and create business models for the technologies. On a far more practical level, villagers will also have the opportunity to decide which of the prototypes they are most interested in, and then work with our partners in Suame Magazine to have these manufactured.

The FLAP buckets and assembly

This is part of an ongoing series of posts on the FLAP bag project, a collaborative effort by Timbuk2, Portable Light and Pop!Tech. We at AfriGadget are helping to field-test these bags that have solar power and lighting on them, and get interviews of the individuals using them.

Day 2: The buckets arrive

This is a continuation of yesterday’s starting video diary, where I received the flaps to the FLAP bag. Saturday morning the package from Timbuk2 was on our doorstep waiting to be opened. The bottom part of the bags had arrived, but there were a few surprises in store for me…

The FLAP bag buckets and assembly from WhiteAfrican on Vimeo.

Next stop Accra, Ghana. I hope that all the kits arrive in one piece, and will start to put them to use as soon as I can.

The FLAP Bags Arrive

This is part of an ongoing series of posts on the FLAP bag project, a collaborative effort by Timbuk2, Portable Light and Pop!Tech. We at AfriGadget are helping to field-test these bags that have solar power and lighting on them, and get interviews of the individuals using them.

Day 1: The flaps arrive

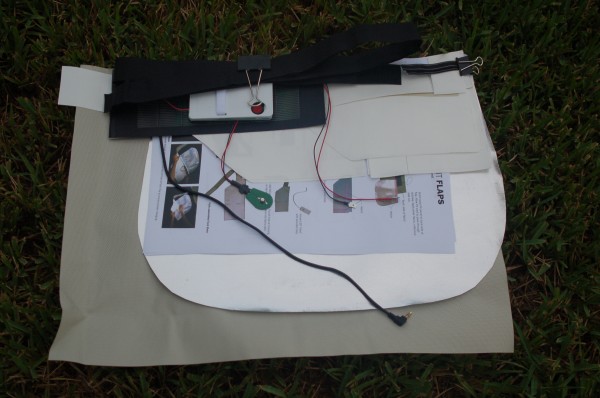

The FLAP bag kits started to arrive Friday evening. The buckets (bottom part of the bag) from Timbuk2 had not yet been delivered at this point, so all I had was the flaps.

Tune in for part 2 later… in the meantime, some pictures: