This post is dedicated to Blog Action Day, where thousands of blogs around the world unite to talk about one theme. This year it is the environment.

Simon Mwangi calls himself a mabati (sheet metal) blacksmith. He takes junk and creates beautiful metal animal sculptures. If you happen by his roadside shop on Ngong Road in Nairobi, you’ll see a number of crocodiles and if you’re lucky, a full sized giraffe.

If you’re in the market for a crocodile, which he sells primarily to hotels, be ready to pay 30,000 Kenya Shillings (about $450). They take about one week to make.

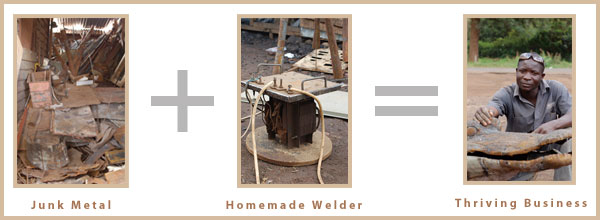

What’s remarkable about Simon, beyond the actual artwork that he fabricates, is that everything he does and works with is made from left over metal junk. Even the welding machines that his team uses are made by the team from leftover metal plates and copper wire. (See an example of the welder at this earlier AfriGadget post)

This is an excellent example of how Africans reuse and recycle to meet their needs. Many times their ingenuity creates thriving businesses, proving that entrepreneurship and environmental needs aren’t mutually exclusive.

(More images in the AfriGadget Flickr Group)