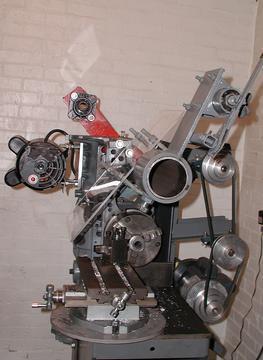

The MultiMachine Group at Yahoo! Groups carries plans for “The Multi-Machine” which is

an accurate all-purpose machine tool that can be built by a semi-skilled mechanic with just common hand tools.

Multi-machines are 3 in 1 machines based on old car engine blocks (a 3-in-1 machine is usually a combination of a metal lathe, mill and drill press). The machines are designed such that they use the tolerances and engineering initially used to create the engine block that is re-purposed as the core of the tool to help guarantee that various components of the machine integrate with a high level of precision.

The machines have a design that not only allows them to be assembled using “elbow grease” but that also allow them to run on alternative power sources where mains electricity is not available. They are also easily adaptable to new purposes by adding on modules.

Plans to build a multi-machine can be found at this link at the The Open Source Machine website.

(via BoingBoing)